Float Glass

Product Description

Float Glass is produced in two types.

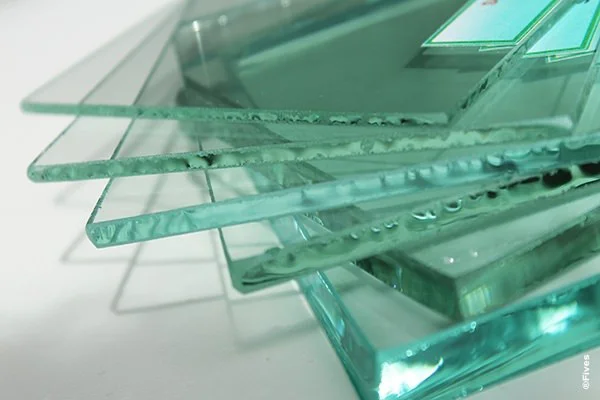

1- Float Glass

This glass is prepared from a combination of raw materials like silica, which is the primary material for making float glass. Besides, sodium carbonate, which makes silica more fluid, is added to it. Lime that causes the impermeability of glass against water is then added, and also materials, including feldspar, sodium sulfate, arsenic, dolomite, and other materials are mixed in the furnace.

It enters the tin bath at a temperature of 1500°C and leaves the bath at a temperature of 650-700°C. It is slowly cooled like a flowing film, and white glass is prepared at the end of the line. White glass is produced in 3mm to 12mm sizes.

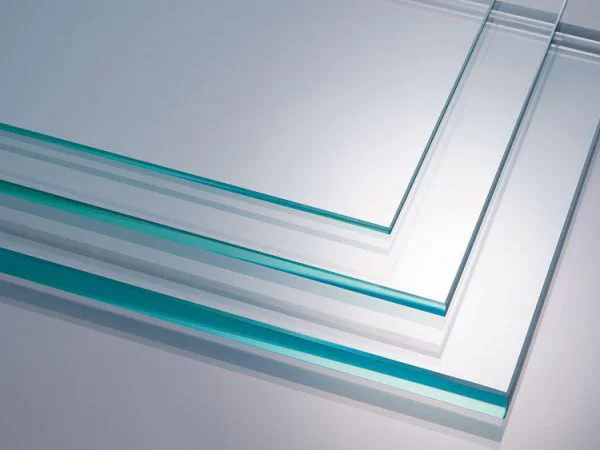

2- Super Clear Glass

This glass is very clear with a colorless color so that it is entirely transparent under the sunlight. As its color is closer to green, it will have less quality and purity. Less iron oxide is exploited in the preparation of this glass.

The Super Clear Glass Characteristics embrace the following items:

– High clarity

– High clarity of vision

– The maximum amount of light and energy transfer

– High security at the time of breaking because of being turned into small pieces

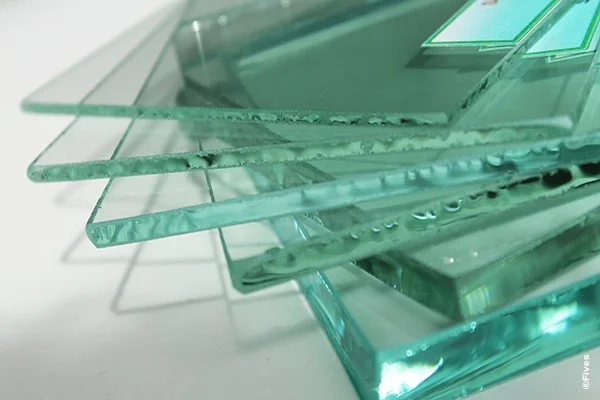

Float Glass and Super Clear Glass are produced in the following dimensions:

321×225

321×250

366×244

180.5×244